Stones are literally the building blocks of any project. In any residential or commercial project, be it flooring, paving, swimming pool and pool decks, sidewalks, walling, garden paths, driveways, steps risers, facades cladding, backyards, porches, landscape patio, interior flooring, interior walls, bathroom floors, bathroom walls, landscape surroundings, kitchen countertops, cabinet countertop, wall-cladding (exterior/interior), facades, roofing, kitchen countertops, back splash, vanity tops, walkways, fireplace surrounds, garden landscaping, flagging, bathrooms, patios, coping, conservatory or lounge, external patio, front entrances, outside areas, and masonry...etc. the importance of natural stones remain inevitable. Overseas customers are often attracted to India by looking at the rich variety of natural stones be it sandstone, slate stone, limestone, porphyry, basalt, quartzite, marble and granites. Being in business for the last 15 years, Rajasthan Slate & Stone Exports Inc. is well known exporter for A Grade Quality natural stones directly from the quarries spread across north India and south India. Wepromoteand export only those natural stones which are best for the overseas markets and having the zero defect in terms of shade, appearance, size, thickness, texture etc. Rajasthan Slate & Stone Exports Inc. is and exporter and supplier of Indian natural stone products to both B2B and B2Cbuyers worldwide.

Going by a slogan, “Happy customers=Healthy business”, we understand how much quality means to our overseas customers. We always keep our customers’wishes on top most priority by delivering them building stones as per their specifications and expectations. Being in export business and dealing with overseas clients, we understand that our customers trust us&it’s our primary duty to maintain this valuable trustlifelong. In order to achieve “this trust” we never compromise on quality and keep a fair check on each and every step at the time of raw material procurement and then during production, processing and at the final packaging stage. Rajasthan Slate & Stone Exports Inc. never fails to satisfy the global customers in the matter of time bound and safe delivery of dimensional stones as well as stone articles.

Step 1

The first step starts from the procurement of the raw stone blocks from the reputed and best established quarries, we check thoroughly each and every stone block before it arrives at the factory for further cutting and processing for export orders. Only our experienced and veteran quality inspectors mark the blocks at the quarries.

Step 2

After selection of the raw material at the quarry, our inspectors mark the stone blocks by our company logo. We select only the best stones and reject the stones which do not qualify as per the standards.

Step 3

After the marking of the raw stone blocks, the blocks despatched to the factory for further processing as per the order we got from the overseas clients.

Step 4

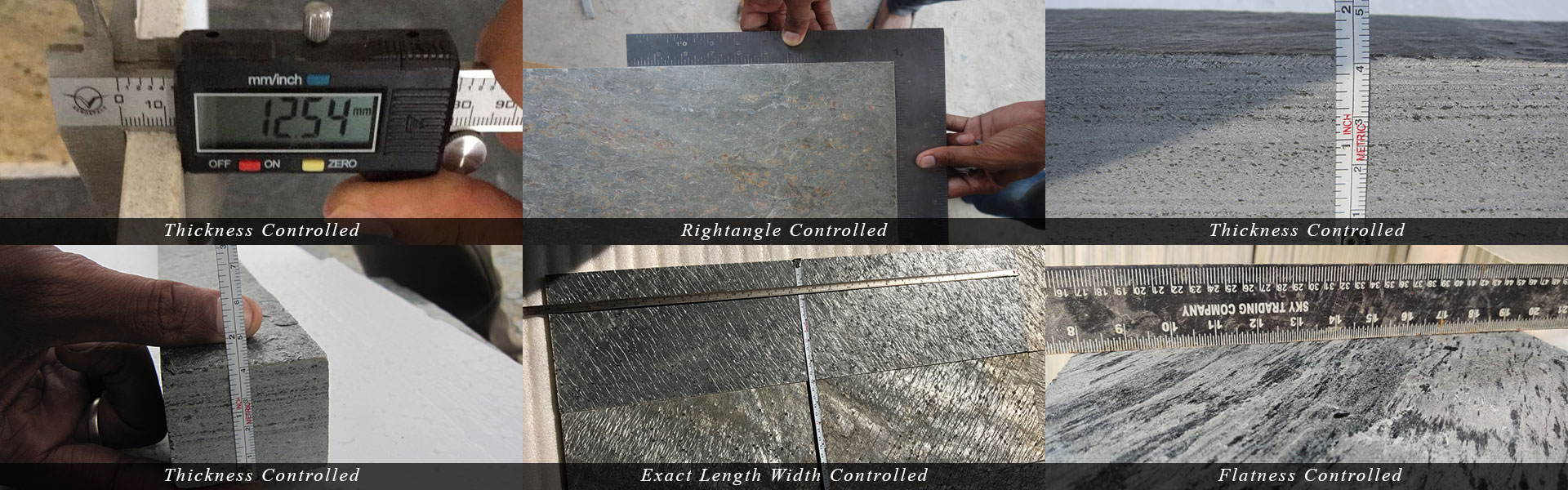

During the production time, our quality checkers keep on watching the material which is coming after sawing. We check the stones on various grounds namely appearance, desired qualities, defects and dimensional specifications. To understand the process deeply please refer to the table below-

| Appearance trait | Quality standards to be matched |

| Colour | Colour should show resemblance with the image on the website. |

| Texture | Texture should be in accordance with the product description. |

| Lines and spots | Lines and spots should be present if the authentic variety also has them. |

| Grain size | Grain size should be in accordance with the product description. |

| Uniform grains | The grains should be uniform |

| Defects | Quality standards to be matched |

| Cracks | Intolerable |

| Fissures | Intolerable |

| Fractures | Intolerable |

| Scratches | Can be corrected by processing |

| Swirl marks | Can be correcting by polishing |

| Broken edges | Can be corrected by processing |

| Repairs | Can be made if the quality of the product is not compromised |

are checked for each and every consignment separately keeping in mind the customer’s specifications.

Even we welcome the III party inspections also…from SGS, TUV, Intertek, Pro Qc, International, Small World, International Inspection Services (p) Ltd., RSJ Inspection Service Limited, Quality Tex India, QIMA, BTCIS - Third Party Inspection Services, Inhouse Incorporation etc. we have no objection…we welcome III party inspectors to check the quality before despatch and during the production stage.

We have deputed experienced as well as young footed team to check the quality at all stages of the production and despatch. Even at the load port also we have ONE container loading in-chargewho checks the wooden crates loading in the container and give us full report after container stuffing and fumigation formalities, the same report we forward to our clients. The duty of this container loading in-charge is to check the intactness, packaging, handling as well as safe loading of containers.

To conclude….once a customer place his order, we conduct regular quality checks during the course of production (for size, thickness, specification, shade, texture etc.) that are as per our order procured. We 100% ensure that our natural stones should comply with global standards which our buyers has communicated.

Tell us about stone color name, size, thickness, quantity and anything else you want us to know about the back splash, facade, inside flooring, inside wall, outside flooring, outside wall project you're working on, we’ll get back to you promptly.